著名医師による解説が無料で読めます

すると翻訳の精度が向上します

ペレットをエチルセルロース粉末でコーティングして、拡張放出を実現しました。エチルセルロース粉末の膜形成能力と、製剤因子(可塑剤の種類と濃度)と硬化条件(硬化温度と時間)の効果を調査しました。The coating formulation was divided into two components consisting of a powder mixture (polymer plus talc) and a mixture of liquid materials (plasticizer plus binder solution), which were sprayed separately into the coating chamber of a fluidized bed coater (Glatt GPCG-1, Wurster insert).The coated pellets were oven-cured under different conditions (60-80 degrees C, 2-24 h) without and with humidity (100% relative humidity).プロプラノロール塩酸塩をモデル薬として使用し、37度C(USP XXVパドル法)の0.1 N HClで薬物放出を研究しました。Despite the high glass transition temperature of ethylcellulose (133.4 degrees C), micronized ethylcellulose powder can be used for dry powder coating by adjusting the coating temperature, amount and type of plasticizer applied, and curing conditions.40% plasticizer and a curing step (80 degrees C, 24 h) were required to achieve complete coalescence of the polymer particles and extended drug release of coated pellets.エチルセルロースコーティングされたペレットは不均一な表面を持っていましたが、15%のコーティングレベルで拡張薬物放出を得ることができました。Because of its high glass transition temperature, ethylcellulose-coated pellets showed unchanged drug release profiles upon storage at room temperature for 3 years.

ペレットをエチルセルロース粉末でコーティングして、拡張放出を実現しました。エチルセルロース粉末の膜形成能力と、製剤因子(可塑剤の種類と濃度)と硬化条件(硬化温度と時間)の効果を調査しました。The coating formulation was divided into two components consisting of a powder mixture (polymer plus talc) and a mixture of liquid materials (plasticizer plus binder solution), which were sprayed separately into the coating chamber of a fluidized bed coater (Glatt GPCG-1, Wurster insert).The coated pellets were oven-cured under different conditions (60-80 degrees C, 2-24 h) without and with humidity (100% relative humidity).プロプラノロール塩酸塩をモデル薬として使用し、37度C(USP XXVパドル法)の0.1 N HClで薬物放出を研究しました。Despite the high glass transition temperature of ethylcellulose (133.4 degrees C), micronized ethylcellulose powder can be used for dry powder coating by adjusting the coating temperature, amount and type of plasticizer applied, and curing conditions.40% plasticizer and a curing step (80 degrees C, 24 h) were required to achieve complete coalescence of the polymer particles and extended drug release of coated pellets.エチルセルロースコーティングされたペレットは不均一な表面を持っていましたが、15%のコーティングレベルで拡張薬物放出を得ることができました。Because of its high glass transition temperature, ethylcellulose-coated pellets showed unchanged drug release profiles upon storage at room temperature for 3 years.

Pellets were coated with ethylcellulose powder to achieve extended release. The film forming ability of ethylcellulose powder and the effect of formulation factors (plasticizer type and concentration) and curing conditions (curing temperature and time) were investigated. The coating formulation was divided into two components consisting of a powder mixture (polymer plus talc) and a mixture of liquid materials (plasticizer plus binder solution), which were sprayed separately into the coating chamber of a fluidized bed coater (Glatt GPCG-1, Wurster insert). The coated pellets were oven-cured under different conditions (60-80 degrees C, 2-24 h) without and with humidity (100% relative humidity). Propranolol hydrochloride was used as a model drug, and drug release was studied in 0.1 N HCl at 37 degrees C (USP XXV paddle method). Despite the high glass transition temperature of ethylcellulose (133.4 degrees C), micronized ethylcellulose powder can be used for dry powder coating by adjusting the coating temperature, amount and type of plasticizer applied, and curing conditions. 40% plasticizer and a curing step (80 degrees C, 24 h) were required to achieve complete coalescence of the polymer particles and extended drug release of coated pellets. Although ethylcellulose-coated pellets had an uneven surface, extended drug release could be obtained with coating level of 15%. Because of its high glass transition temperature, ethylcellulose-coated pellets showed unchanged drug release profiles upon storage at room temperature for 3 years.

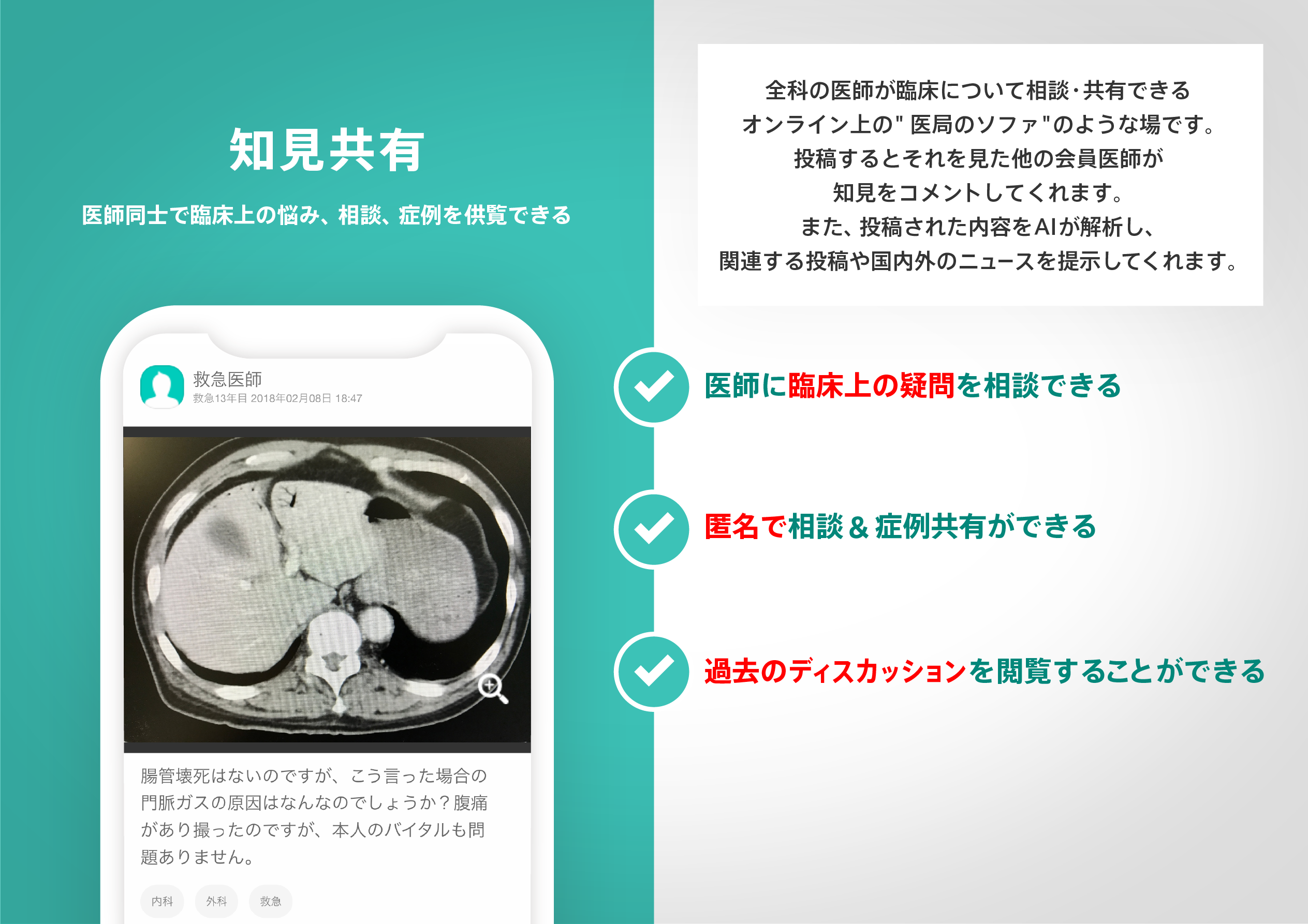

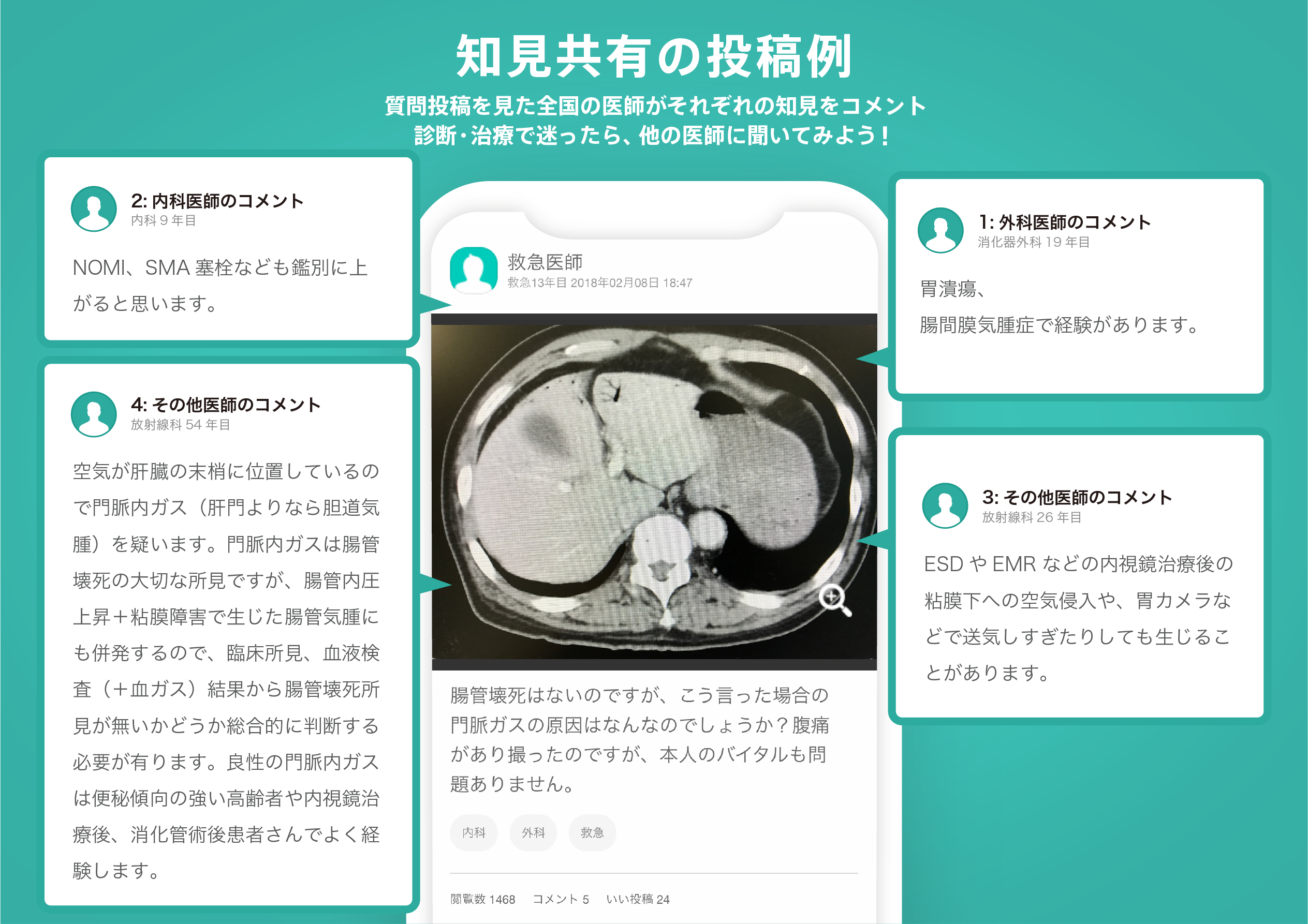

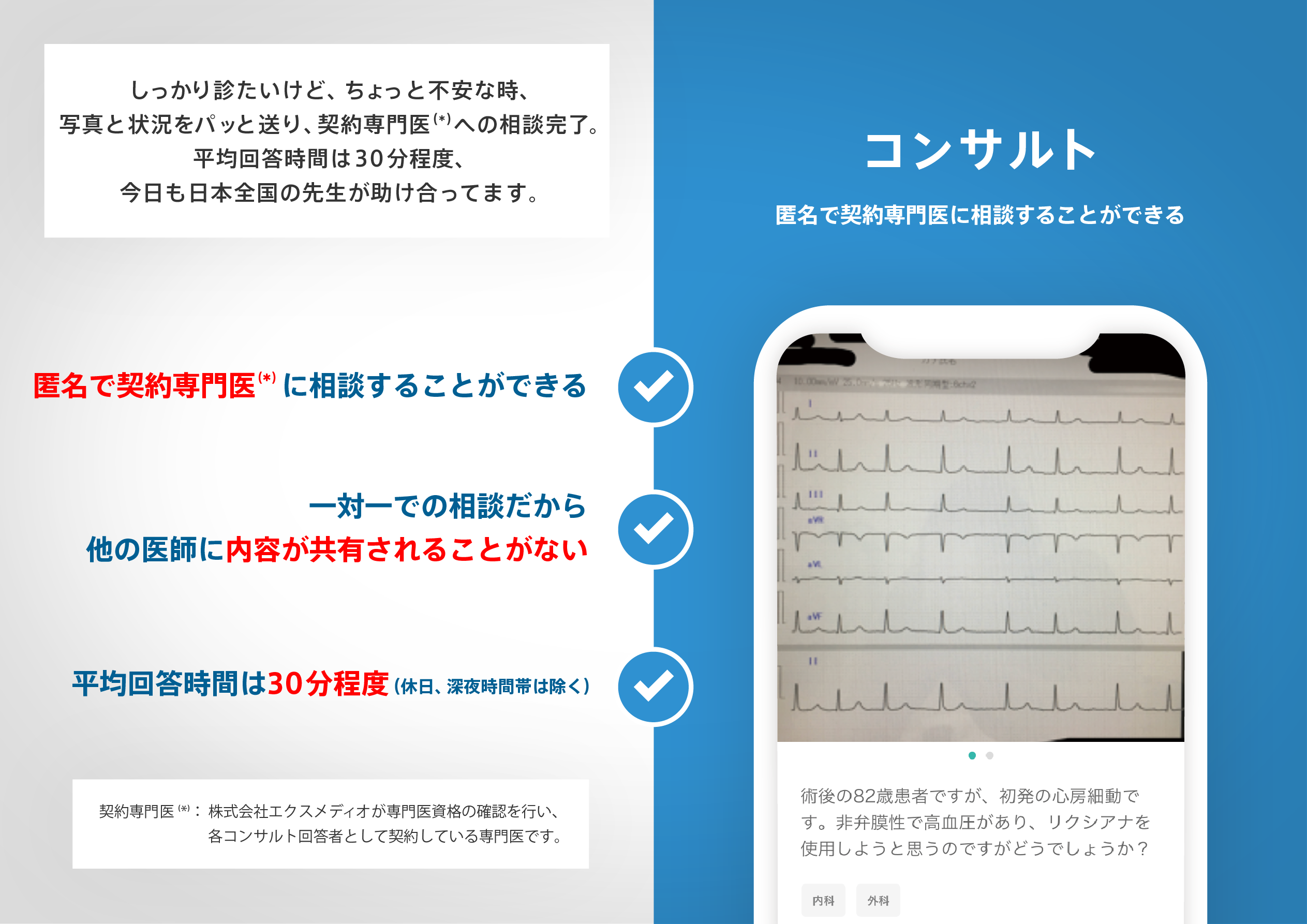

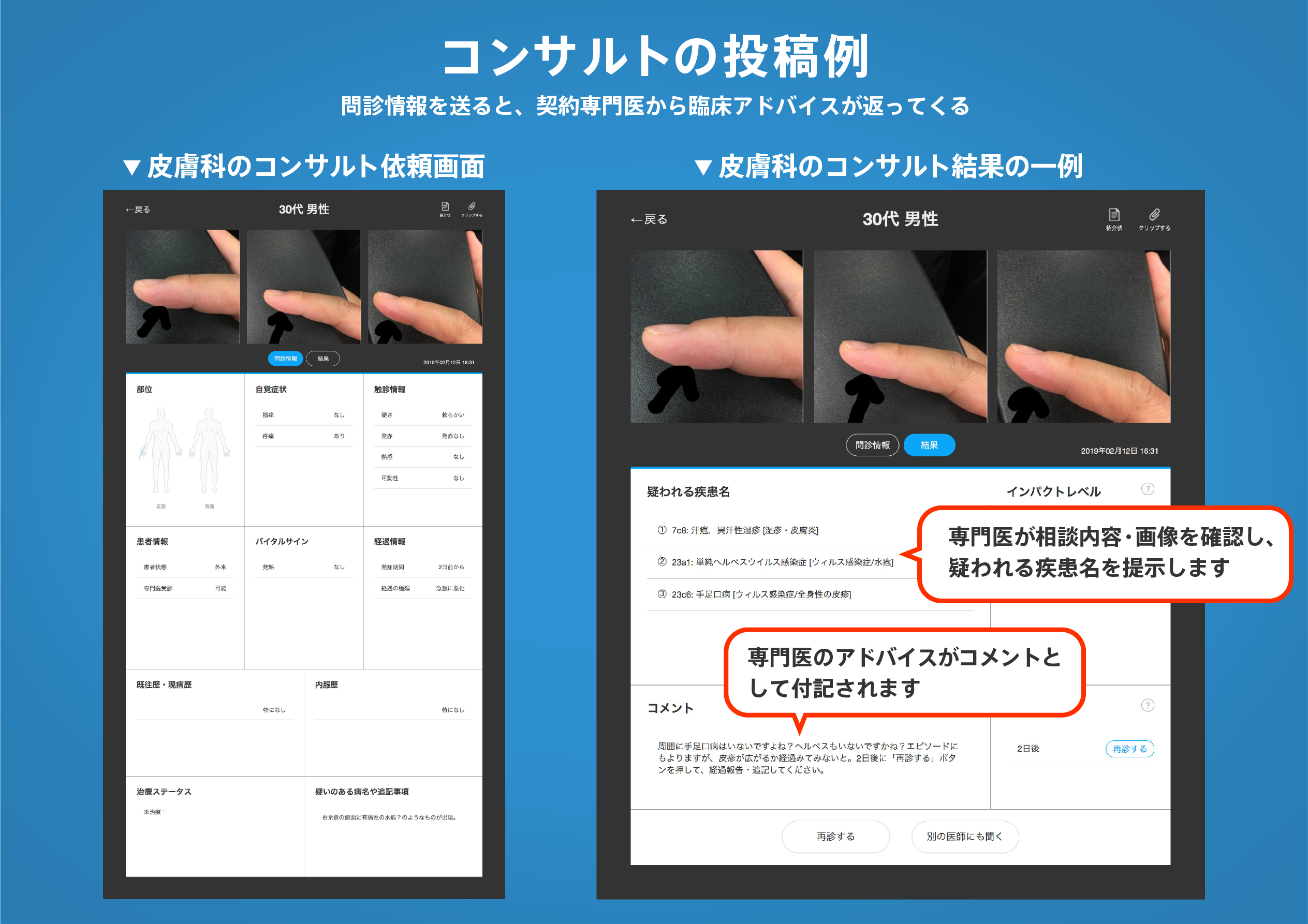

医師のための臨床サポートサービス

ヒポクラ x マイナビのご紹介

無料会員登録していただくと、さらに便利で効率的な検索が可能になります。